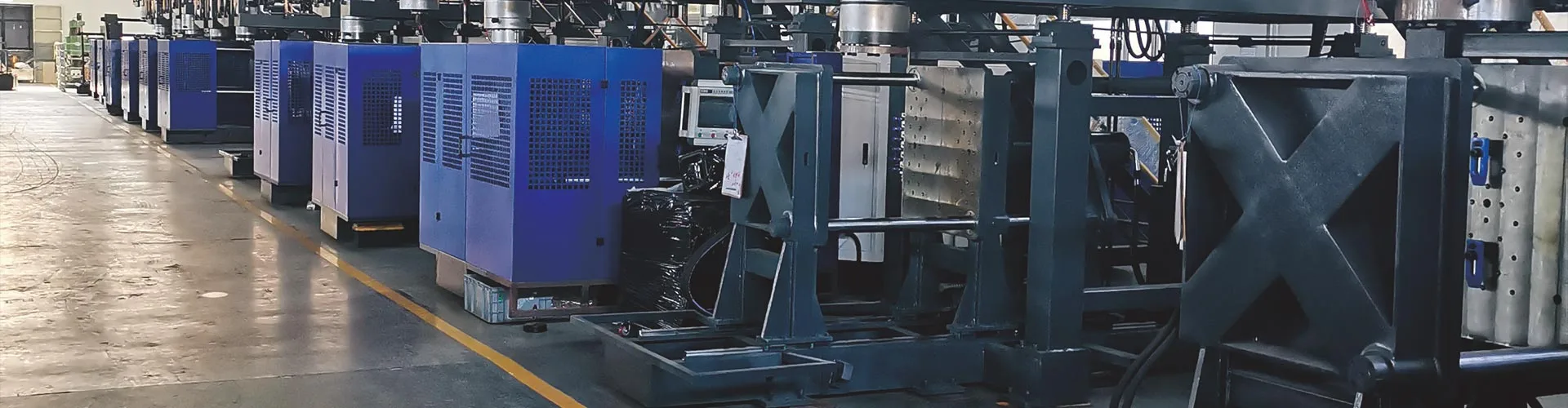

Industry Expertise and Innovation

Kinggle has been dedicated to the blow molding machine industry for 26

years, demonstrating not only our unwavering focus and commitment but also

our deep understanding of technological innovation and customer needs. We

have a team of 15 professional blow molding engineers specializing in all

aspects of the process, including equipment design, process development,

and production commissioning. With an average of over 10 years of industry

experience, many team members have contributed to national and

international large-scale projects, focusing on equipment development and

technical breakthroughs.

Guided by our mission to "Let the blow molding production more relax", we

continuously introduce more efficient and intelligent equipment. For

instance, to meet the demand for producing 30L double-layer drums, we

developed a unique multi-layer co-extrusion technology that not only

enhances product quality but also reduces raw material costs. Our

engineering team is consistently driven by customer needs, ensuring that

every piece of equipment delivers optimal economic benefits in real-world

production.

Precise Cost Calculation and Optimization

Kinggle's sales team leverages professional market research and data

analysis to help customers accurately predict project costs and returns.

For instance, in customizing a production plan for a client, we optimized

energy consumption, mold design, and production processes based on

early-stage cost calculations and sales forecasts. This approach reduced

energy expenses by nearly 20% and unit product costs by 15%, enabling the

client to recover their investment in a short timeframe.

Kinggle's refined cost management solutions are ideal for small businesses

seeking quick returns or large enterprises aiming to optimize profits,

creating long-term value for our customers.

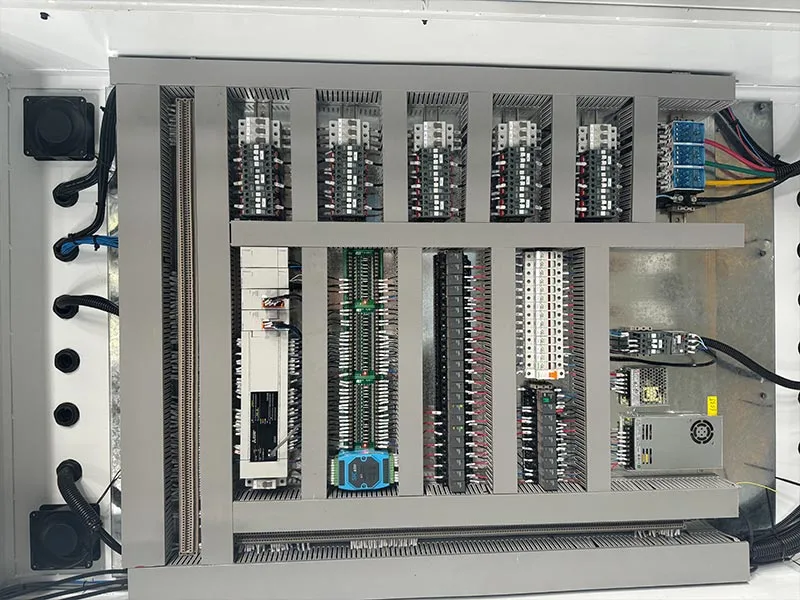

Stringent Quality Control

Before shipment, Kinggle conducts at least 3,000-cycle high-pressure tests

on every machine, simulating prolonged high-load production environments

to ensure stability and durability. For example, our 60L (KGB90A) blow

molding machine successfully passed a continuous 72-hour full-load test,

demonstrating exceptional pressure resistance and consistent molding

performance.

Each machine undergoes comprehensive quality inspections with detailed

records of test data and performance metrics, giving customers confidence

in both their purchase and long-term use.

Comprehensive After-Sales Service

Kinggle provides more than just equipment; we offer a complete service

ecosystem. We have established a 1VN (one-to-many) after-sales team, where

each customer is assigned a dedicated service manager who supports them

throughout the entire process—from installation to ongoing maintenance. In

addition, we offer detailed video tutorials covering equipment operation,

troubleshooting, and production optimization, helping customers quickly

master essential skills.

For example, one of our clients in the daily chemicals industry achieved

stable mass production and gained a market advantage just two weeks after

equipment delivery and team training. To address labor shortages, Kinggle

also assists clients with talent recruitment and skill development,

helping them build an efficient production team.

Industry Challenges and Process Optimization

Kinggle’s design team deeply understands the challenges within our

clients’ industries and actively participates in product development and

process optimization. For example, when designing a production plan for an

automotive parts client, we redesigned the blow molding mold structure,

increasing raw material utilization by 25% while reducing product weight.

This made the client's automotive components more aligned with

environmental and lightweight trends.

Through these targeted process improvements, the client not only reduced

production costs but also gained a technological advantage in the

competitive market.

In-Depth Industry Research and Automation Support

Kinggle’s extensive experience across multiple industries enables us to

provide comprehensive automation solutions. For example, we designed a

fully automated blow molding and downstream processing production line for

a toy manufacturer, including automatic trimming, inspection, and

packaging functions. This solution increased production efficiency by 40%

and significantly reduced human error, helping the client achieve a more

efficient and flexible production process.

Such solutions allow clients to quickly respond to market demands and gain

a competitive edge.